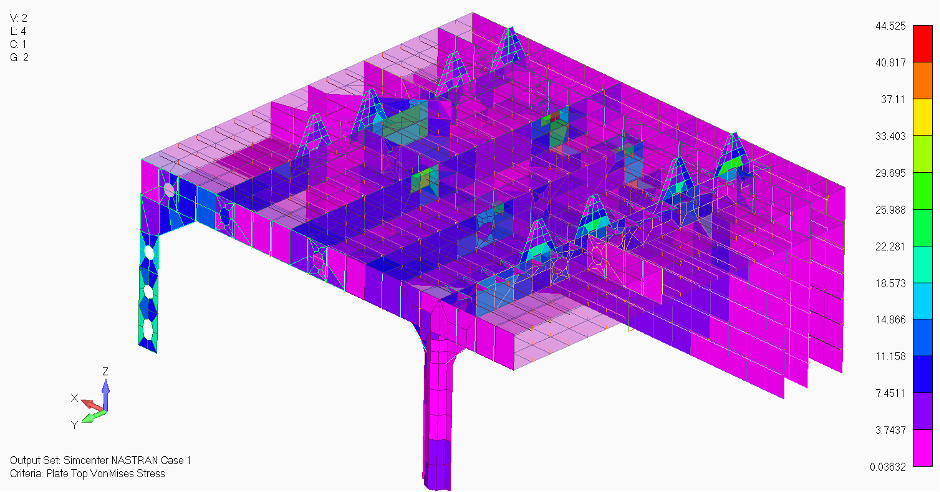

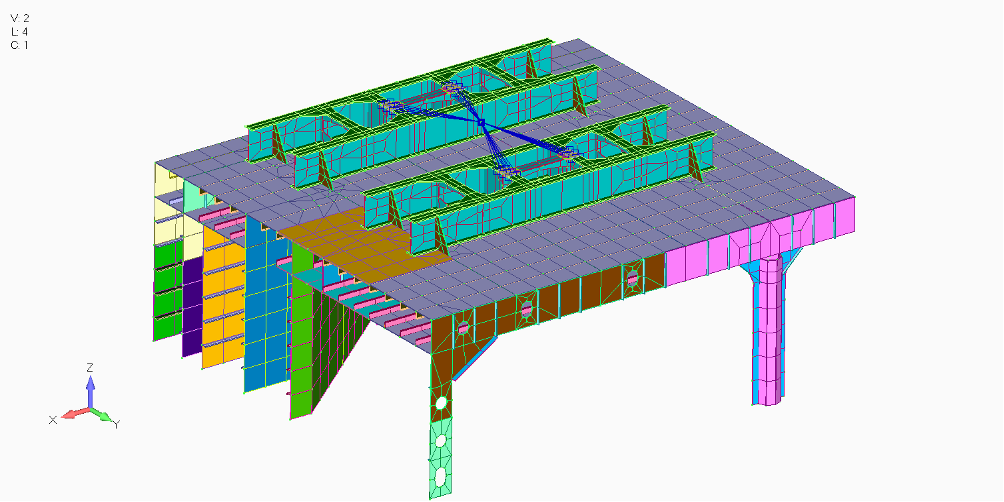

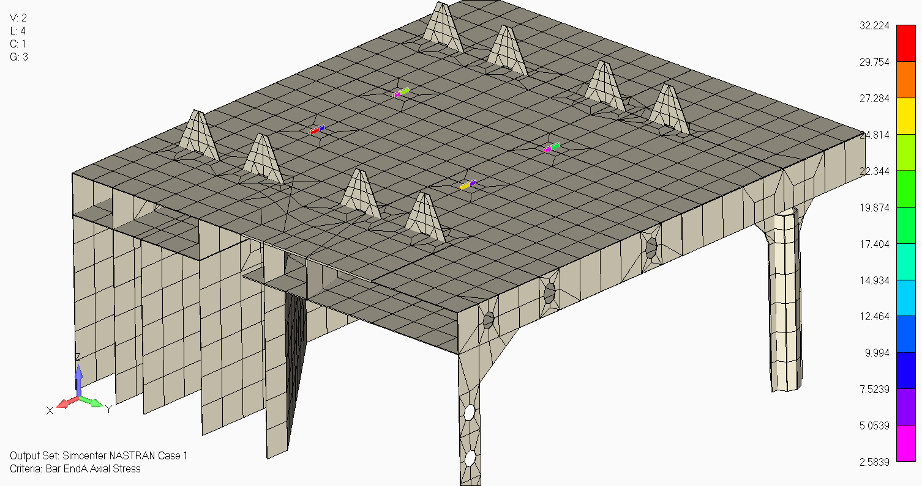

Our structural analysis team used rigid elements connected to the equipment foundation to apply the equivalent forces and moments in order to assess their effect on the connecting brackets, stoppers, and the main deck structure. As a very conservative assumption, all extreme values were considered simultaneously applied on the model. The computed yield utilisation factor for plates and for stiffeners was lower than the permissible factor of 0.8.

Given the low levels of calculated stress and considering the urgency of this gangway installation, no further analysis using a finer mesh model was considered necessary.

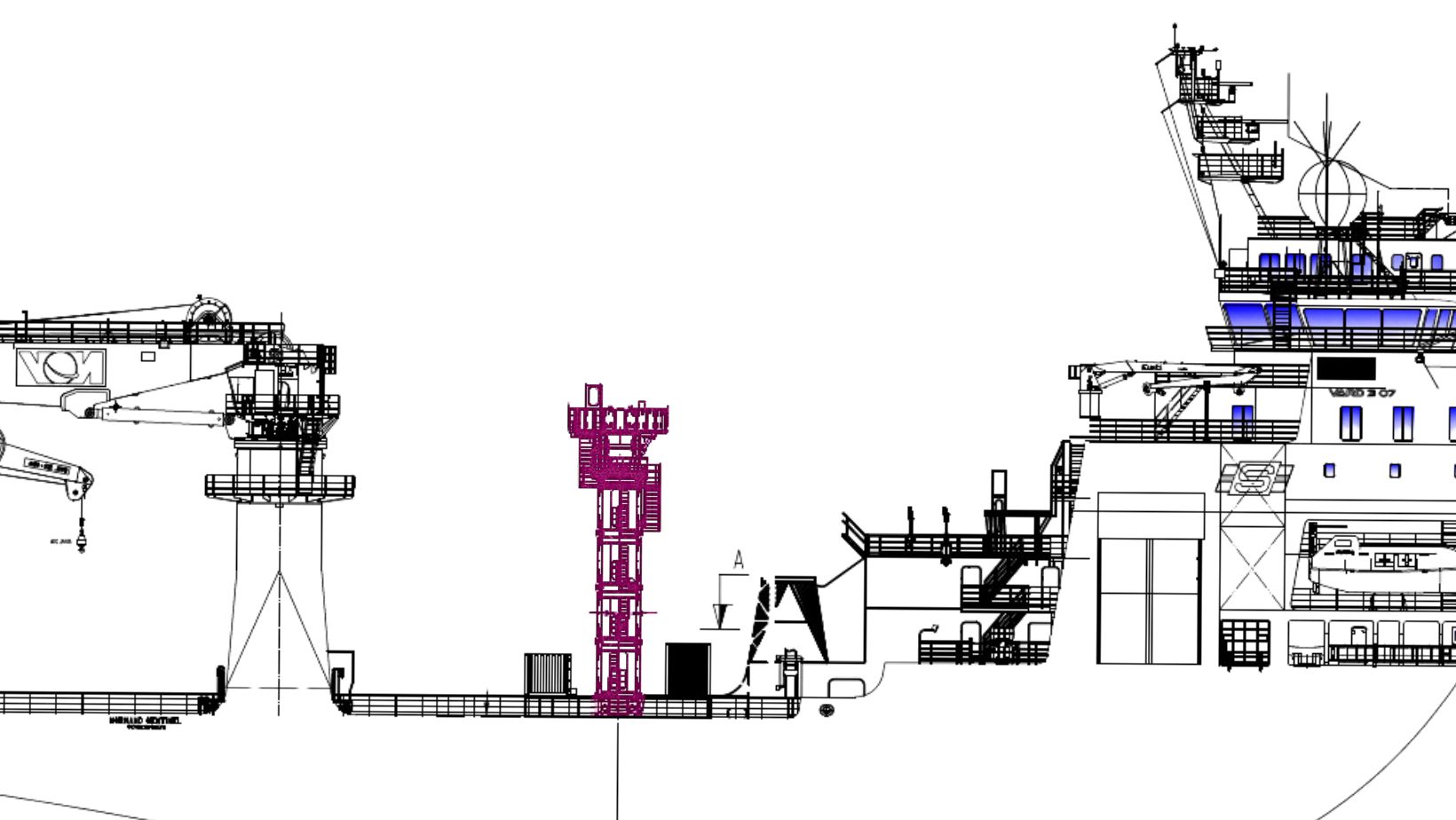

Once the structural analysis was completed, the results were handed over to our design team which translated the information into a structural drawing for Class Approval.