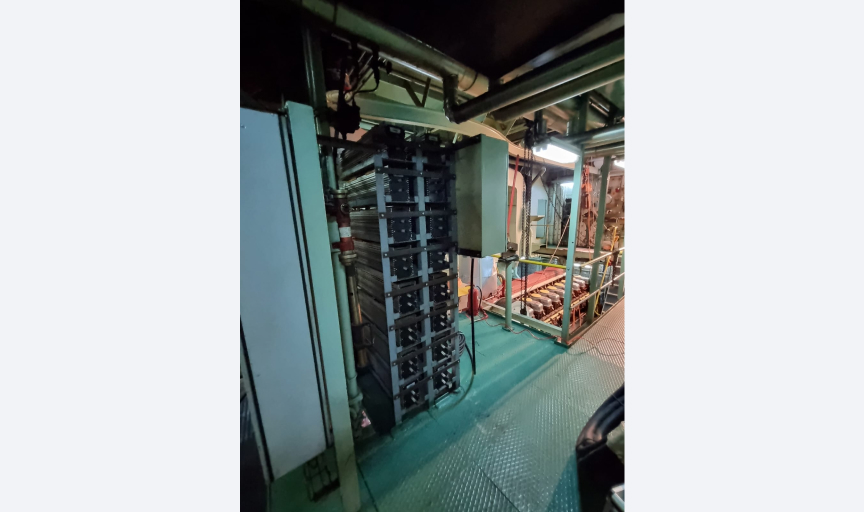

The project’s execution phase commenced with our engineering and operations teams collaborating to gain a comprehensive understanding of our client’s objectives and constraints, as well as to familiarize themselves with the MV Mygan, the designated vessel for the system. To kick things off, our team boarded the MV Mygan to conduct a thorough 3D laser scan of the project environment.

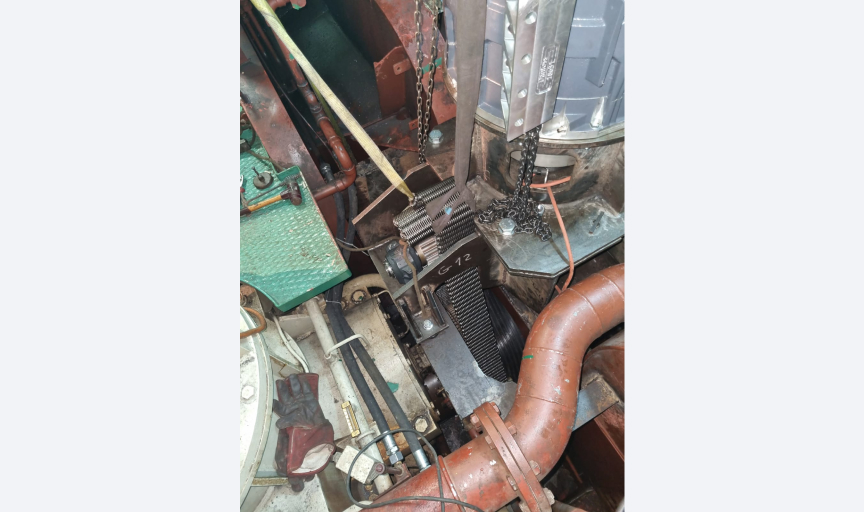

Our project team, composed of mechanical, electrical, systems, and installation engineers, collectively delved into the intricacies of the challenge. We identified a core issue that had the potential to impede the project’s success: the connection and the absolute alignment between the vessel’s shaft and the generator-motor.