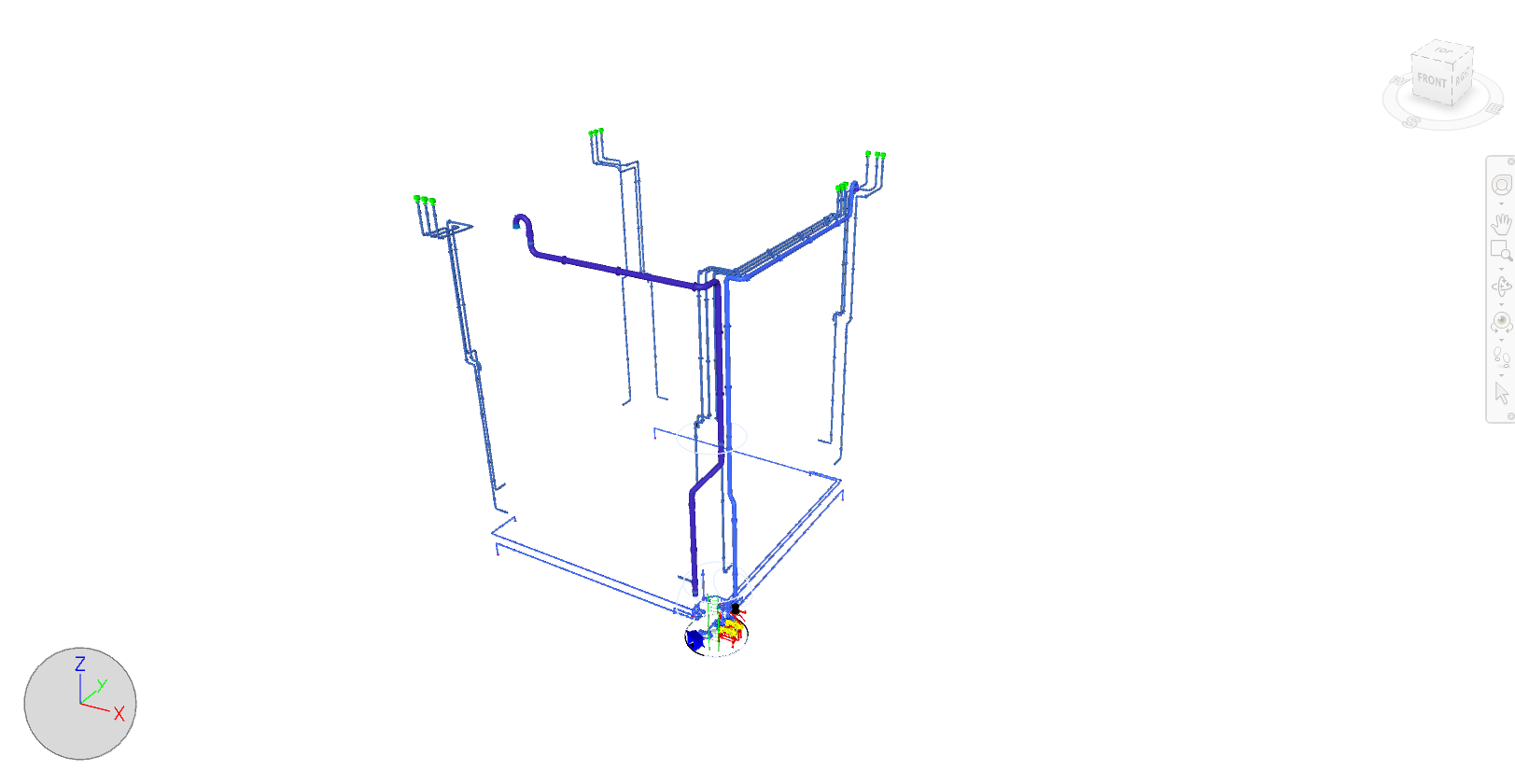

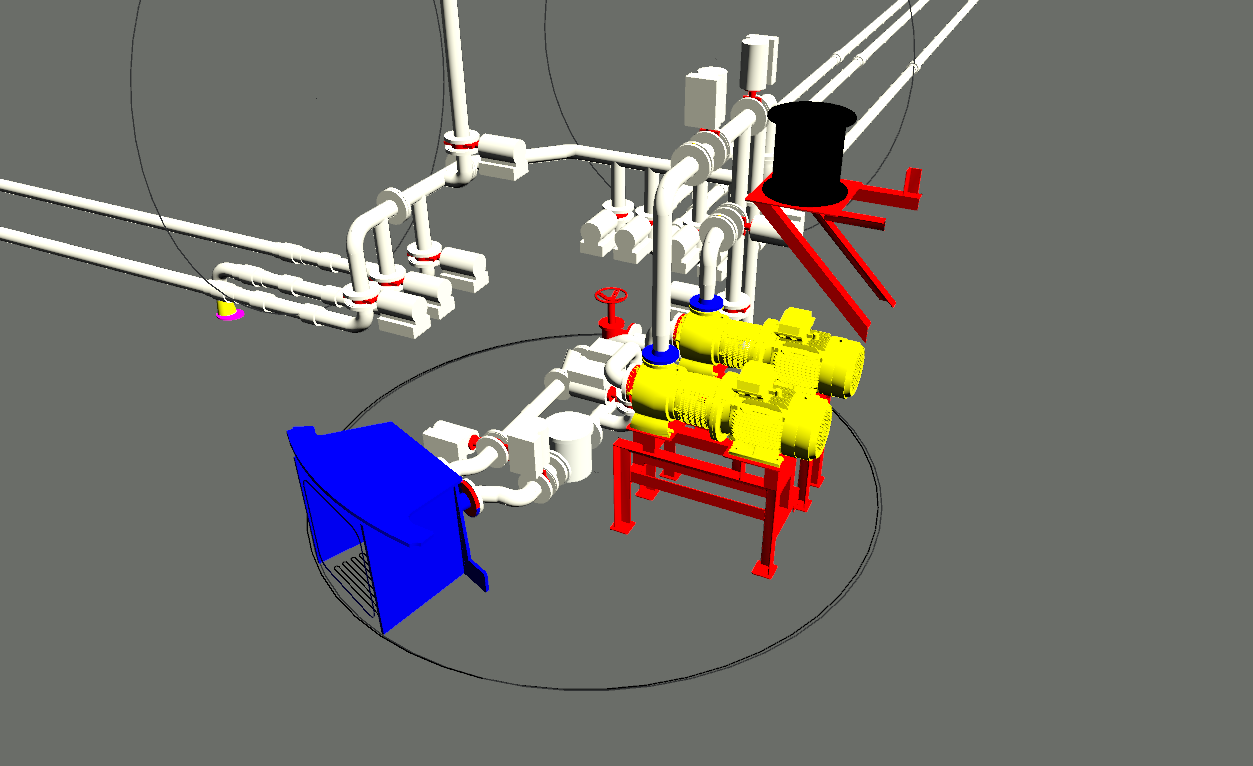

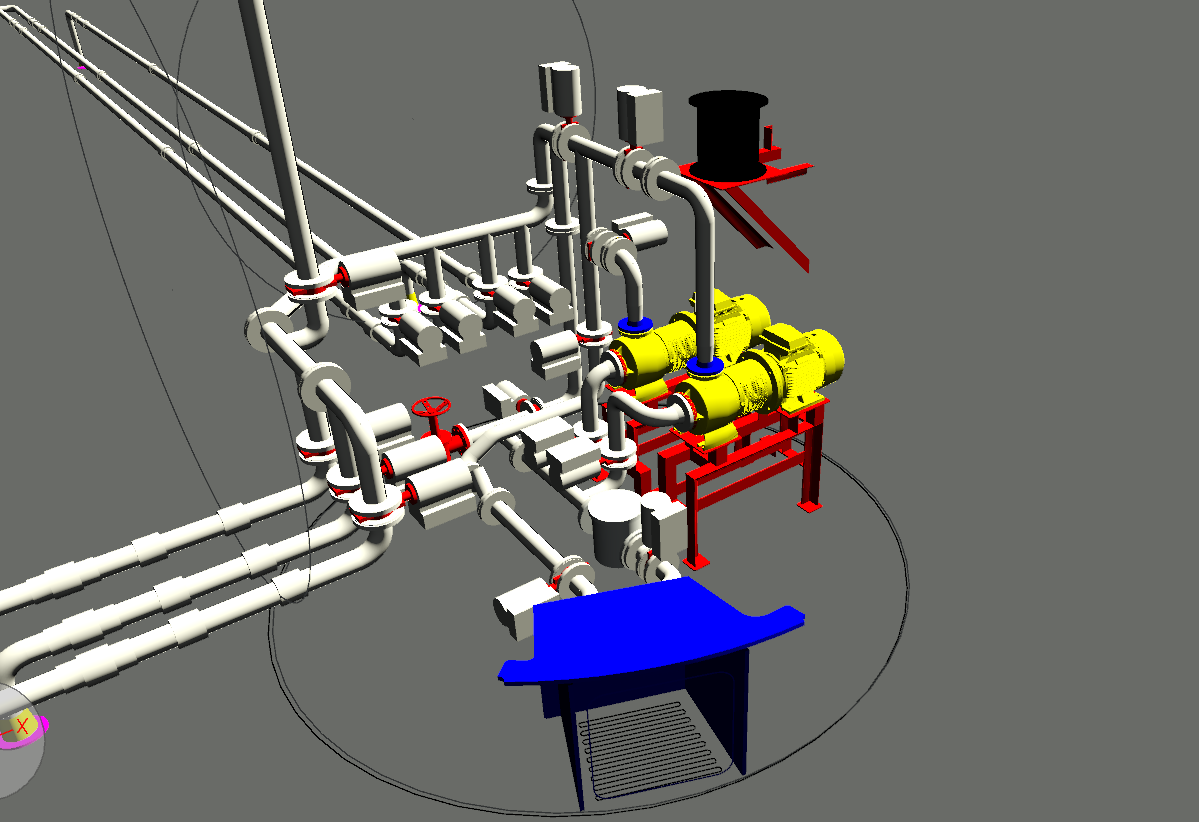

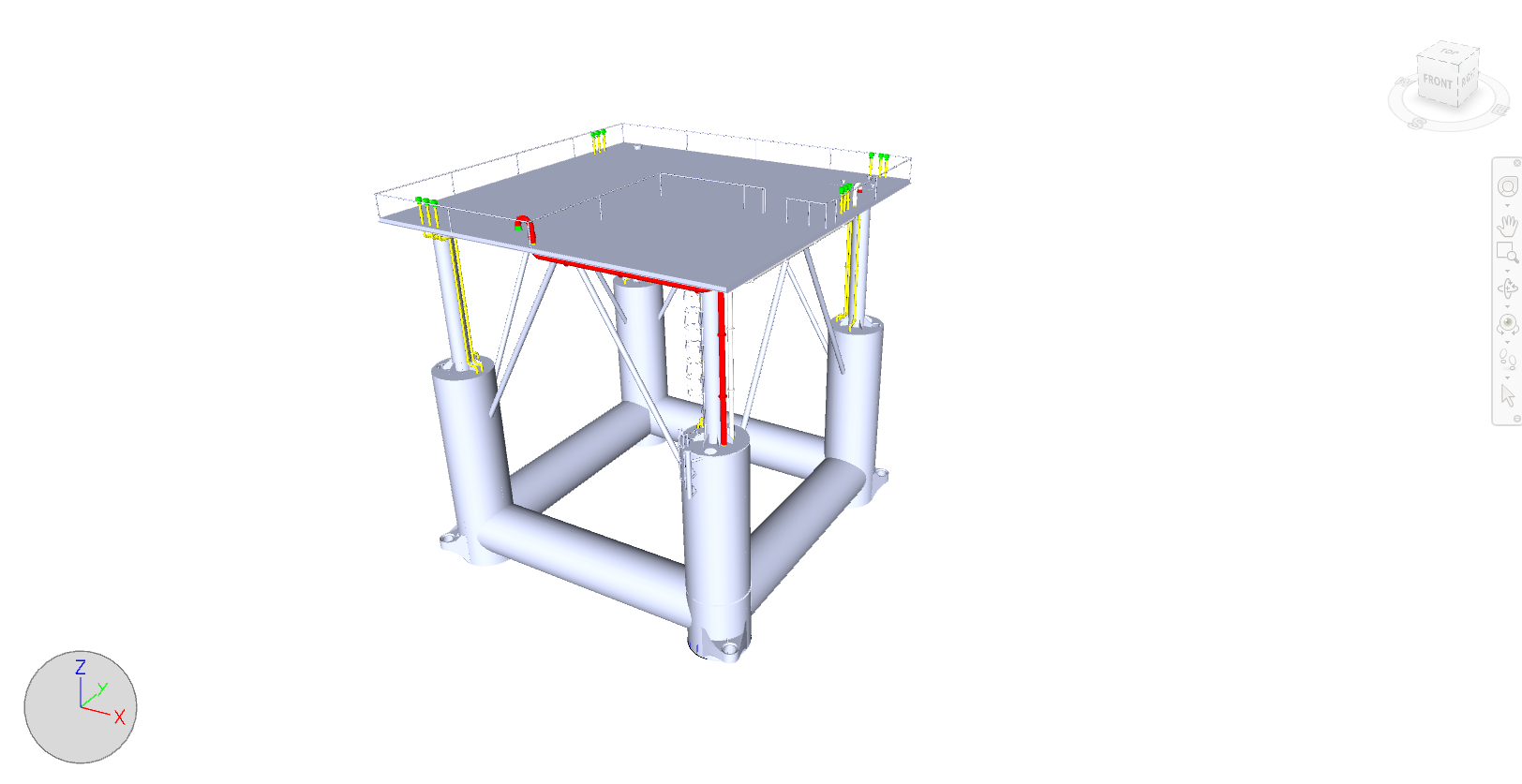

- Complete 3D modeling and detailed design of ballast, ventilation, and tank instrumentation systems, including collision checks and execution drawings.

- Prefabrication of equipment foundations, piping spools, valve supports, and seawater chesons.

Engineering and 3D Modeling