2025 was a defining year for GLO Marine. It marked a step change in the scale, responsibility, and technical complexity of the projects delivered across our global portfolio. More vessels, more systems, and more locations came under our scope, requiring a level of coordination and execution that goes far beyond conventional marine engineering.

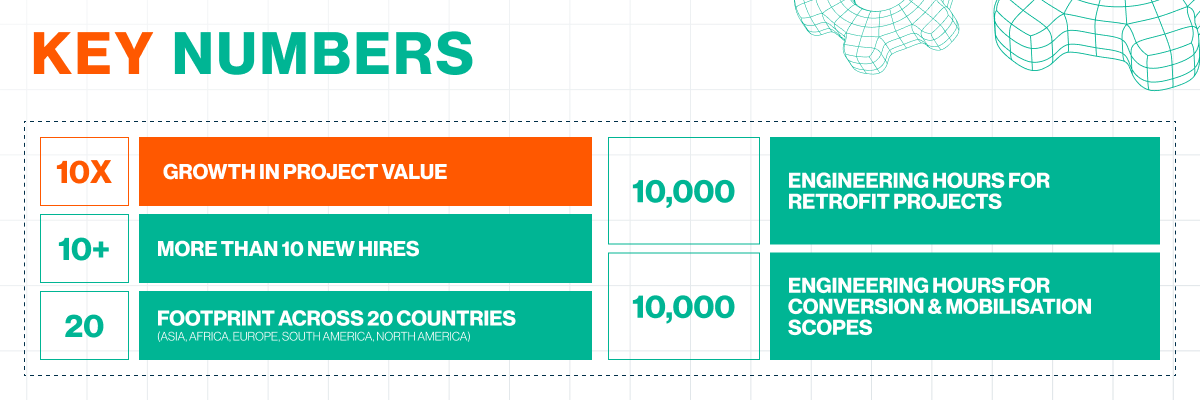

As we move toward 10 years of GLO Marine in 2026, the number ten appears naturally across our 2025 performance. It shows up in project value growth, in the number of systems supported, and in the scale of our international operations. These are not symbolic figures. They reflect a company that has matured into a delivery partner for complex retrofit and upgrade programmes across the world fleet.

Global engineering and project delivery across 20+ countries

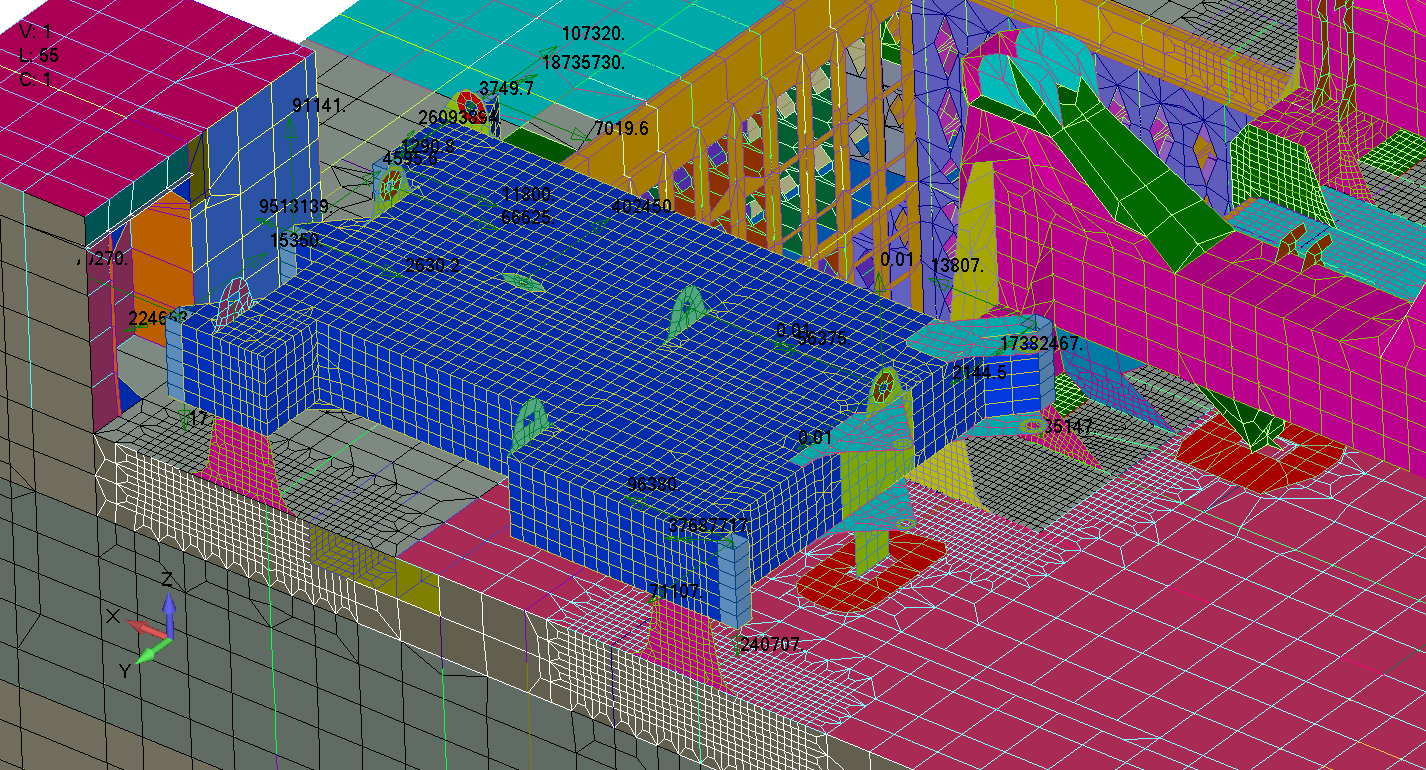

In 2025, GLO Marine delivered more than 20,000 hours of engineering and project support across projects in over 20 countries. These projects were executed under a wide range of regulatory frameworks, class requirements, and commercial structures, from European shipyards to offshore and international trading fleets.

Our role was to absorb this complexity and convert it into solutions that could be implemented onboard without operational disruption. Whether supporting a retrofit in a busy port or coordinating upgrades during offshore operations, GLO Marine ensured that approvals, interfaces, and installation sequences aligned with real-world vessel schedules.

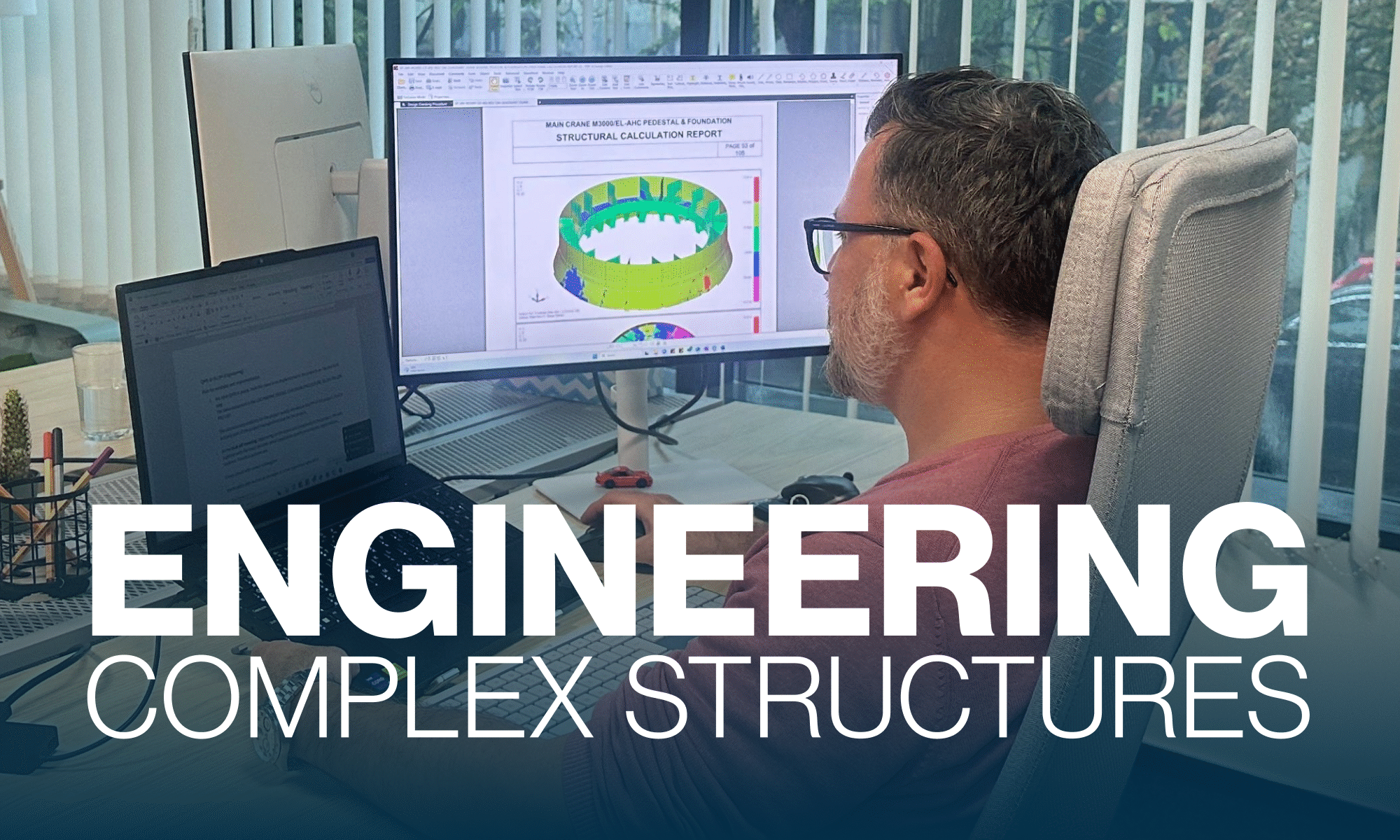

Scaling to multi-million Euro retrofit projects

A major milestone in 2025 was the tenfold increase in project value delivered by GLO Marine. While typical projects in 2024 were in the range of €400,000, our largest project in 2025 reached €4 million. This growth reflects the trust placed in us to manage larger, more integrated scopes that combine engineering, procurement, and installation.

As project values increase, so does the need for tighter control of interfaces, schedules, and risk. In 2025, GLO Marine strengthened its planning and execution frameworks to ensure that even the most complex retrofit programmes were delivered with predictability and technical integrity.

Strengthening engineering, project management, and commercial teams

To support the growth in project scope and complexity, GLO Marine expanded its team with more than ten new professionals across engineering, project management, and sales. This was a deliberate investment in delivery capability, ensuring that technical design, commercial development, and execution remained aligned as more vessels and systems entered the portfolio.

This expansion allowed GLO Marine to manage multiple large projects in parallel, while maintaining the level of detail and control required for retrofit work on operating vessels.

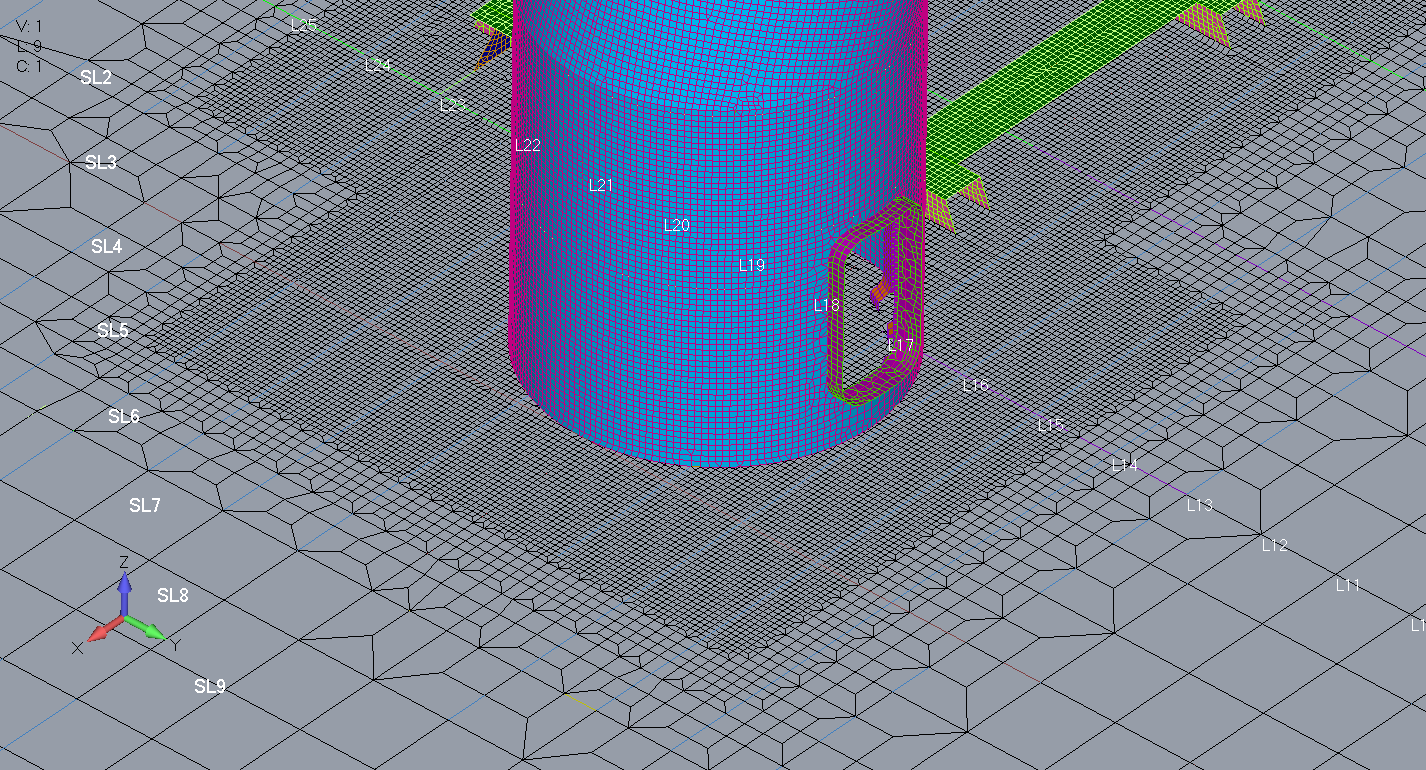

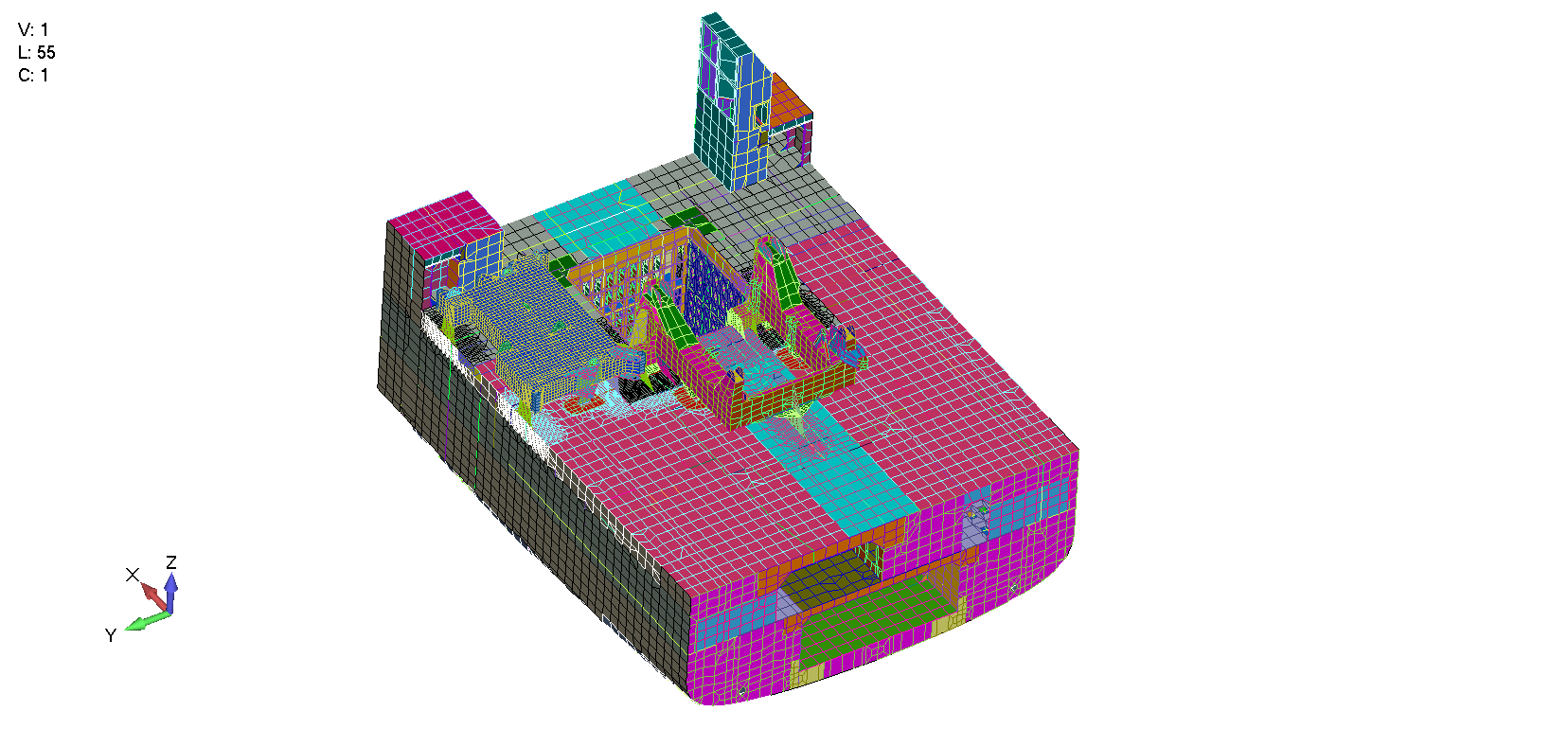

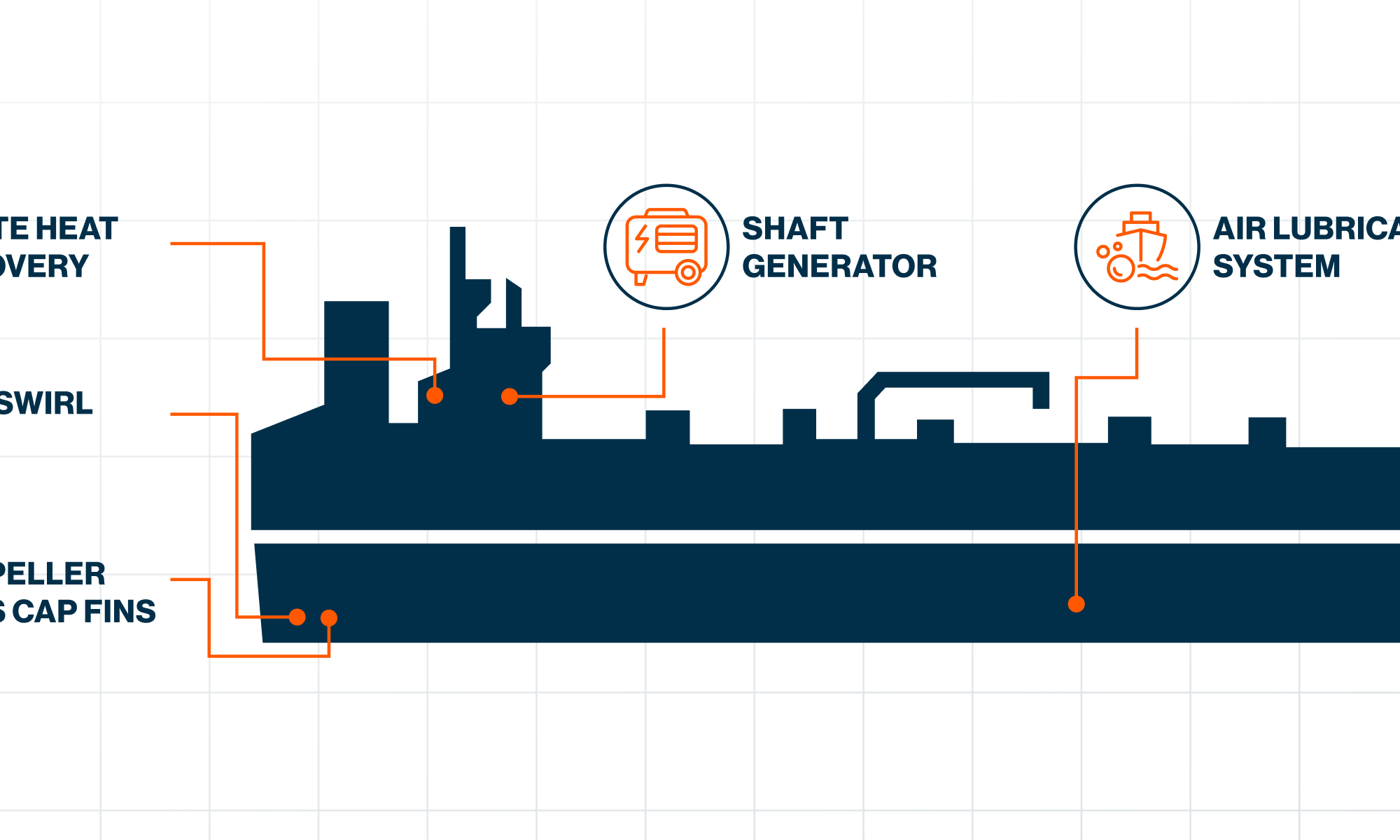

Supporting more than 10 critical onboard systems

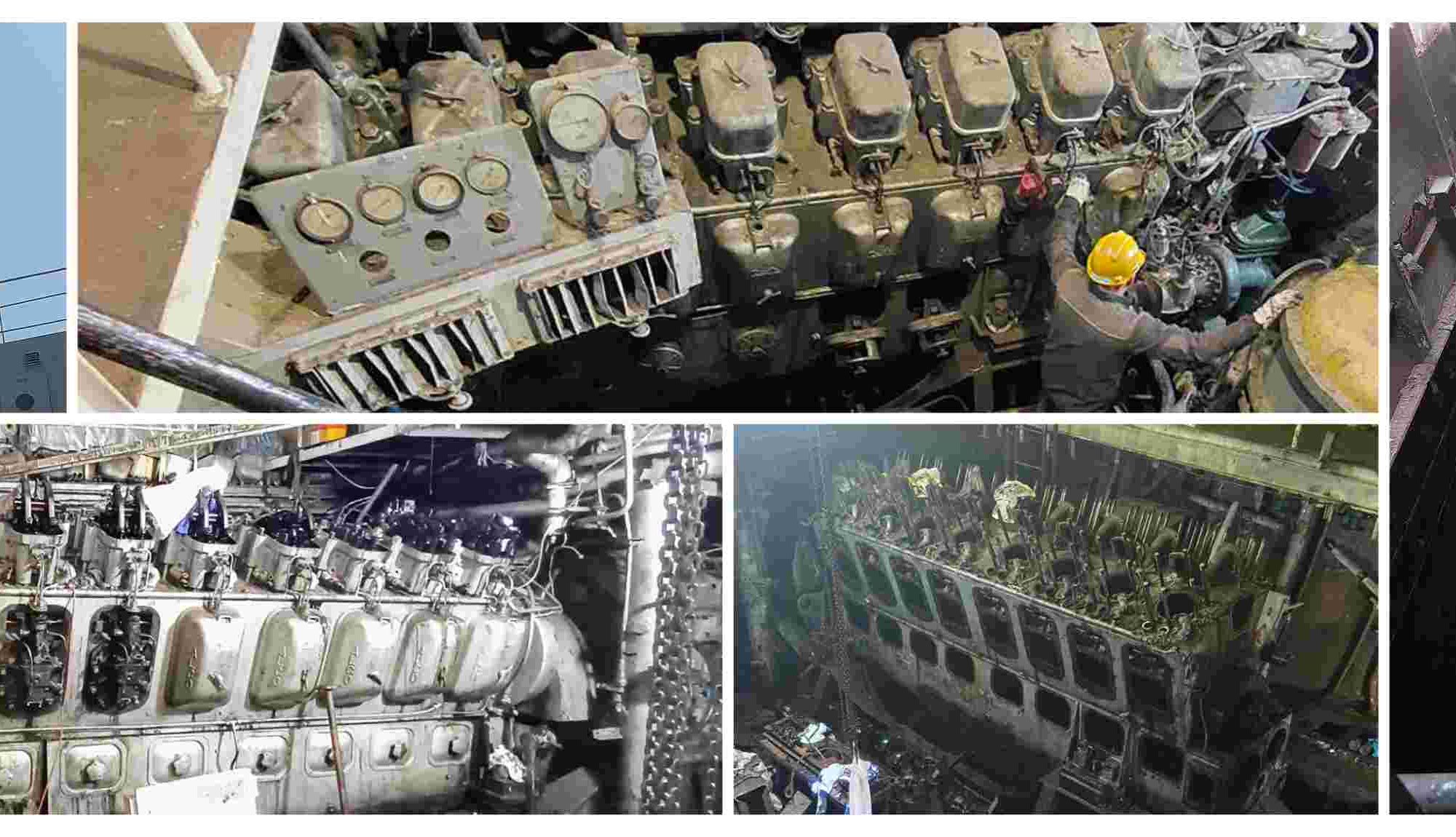

Throughout 2025, GLO Marine worked across more than ten types of onboard systems, including water treatment, bilge, fuel oil, boilers, sea water cooling, firefighting, exhaust gas cleaning systems, and sea chests. Many of these systems were upgraded or retrofitted within limited time windows, often while vessels remained in commercial operation.

Delivering under these conditions requires more than engineering drawings. It requires detailed installation planning, coordination with ship crews and yards, and the ability to adapt when conditions onboard change. These are the environments where GLO Marine’s integrated engineering and project teams deliver the greatest value.

Launching GLO Marine’s production capability

In 2025, GLO Marine also took a strategic step forward by developing its own production unit. This allows us to better control fabrication quality, delivery timelines, and engineering interfaces, reducing dependency on external suppliers and increasing execution certainty.

By integrating production into our delivery model, GLO Marine can respond faster to project changes and support a more efficient transition from design to installation, strengthening our position as a full-scope retrofit and upgrade partner.

Looking ahead to 10 years of GLO Marine

2025 was a year of measurable progress. The team grew, project values increased, the international footprint expanded, and our delivery model matured. As GLO Marine approaches its tenth year in 2026, we do so with a platform designed for large-scale retrofit, decarbonisation, and offshore engineering projects across the global fleet.

For shipowners, fleet managers, and technical operators, this means working with a partner that understands not only how systems are designed, but how they are delivered, installed, and made to work onboard under real operational conditions.

Plan with GLO Marine your next retrofit or upgrade project

If you are planning a vessel retrofit, decarbonisation upgrade, or complex onboard modification, GLO Marine can support you from engineering through to installation. Our teams work globally, across multiple vessel types and regulatory environments, delivering solutions that are designed to perform in service, not just on paper.

Contact GLO Marine today to discuss your project requirements and explore how our engineering, production, and delivery teams can support your fleet.