Improving energy efficiency in commercial shipping increasingly relies on solutions that enhance propulsion performance without introducing unnecessary operational complexity. Among the wide range of retrofit options available today, propeller upgrades stand out for their reliability, cost-efficiency, and ability to deliver immediate gains. These technologies can be fully integrated during scheduled dry-dockings, making them highly accessible for shipowners operating in Europe, the Black Sea region, and beyond.

At GLO Marine, we evaluate these upgrades not as general solutions but as precision tools that must be matched carefully to a vessel’s hydrodynamic behaviour and operating profile. Below, we highlight three propulsion-enhancing technologies that consistently provide meaningful energy savings across different ship types.

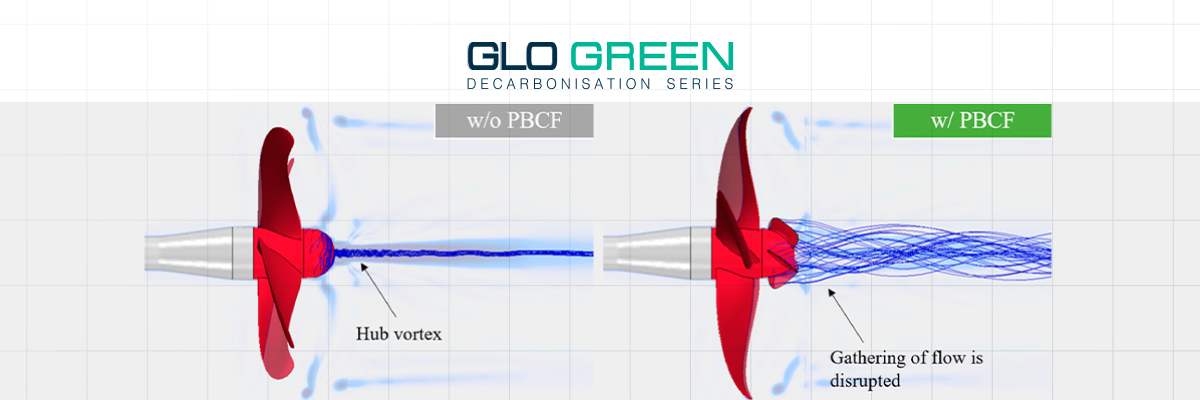

1. Propeller Boss Cap Fins (PBCF): Minimising energy loss at the propeller hub

The formation of a strong hub vortex is one of the less visible, but highly influential contributors to propulsion inefficiency. The Propeller Boss Cap Fins (PBCF) system addresses this by reshaping the flow around the propeller hub, transforming an otherwise wasted energy pattern into more productive thrust.

Key advantages

- Typical fuel reduction of around 2%, with certain vessels experiencing higher gains

- Straightforward retrofit during dry-docking

- Zero-maintenance design with no moving elements

- Works effectively across most single-screw configurations

Engineering principle

The fins mounted on the redesigned boss cap weaken the typical swirling motion behind the propeller. With the vortex suppressed, the thrust curve becomes smoother, the wake field stabilises, and the engine’s delivered power is utilised more effectively.

Integration considerations

Installation focuses on removing the existing cap, fitting and aligning the fin-equipped cap, and verifying clearances. Once installed, PBCF operates passively and requires no crew interaction.

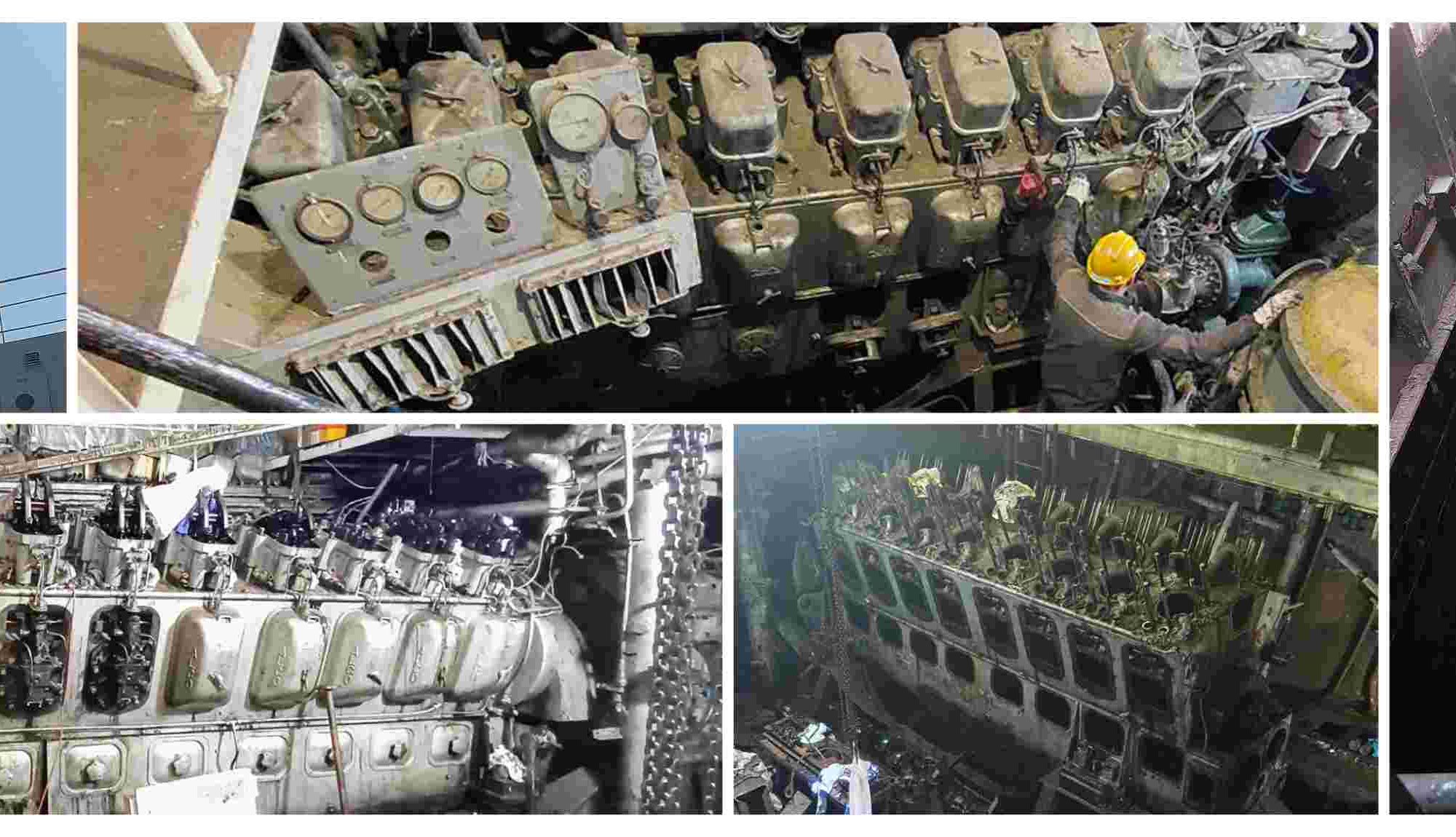

2. High-efficiency propeller designs and reblading: Tailoring propulsion to real-world operation

Many vessels were originally engineered for service speeds that no longer reflect their current operational reality. Slow steaming and revised charter patterns have changed how ships use power day-to-day. This makes propeller optimisation or reblading a particularly strategic upgrade.

Performance impact

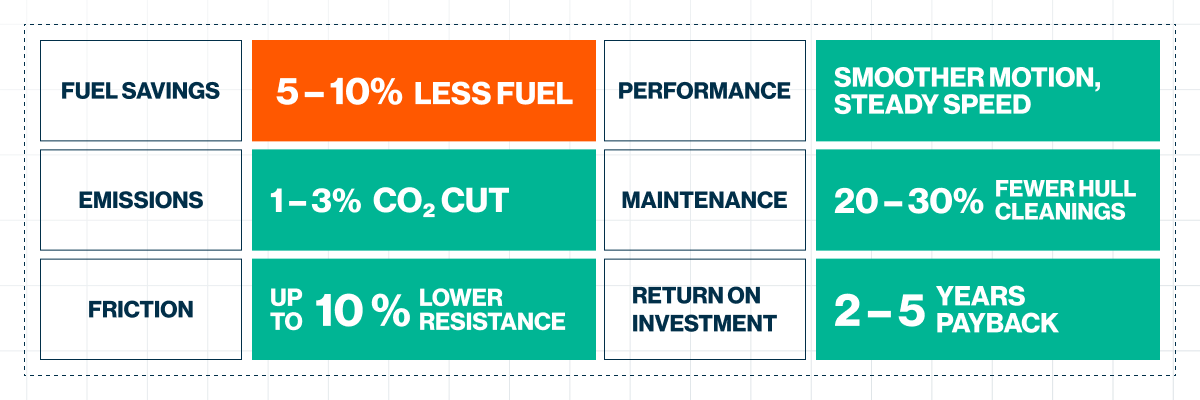

- Fuel savings between 5–10%, depending on vessel type and operating envelope

- Reduced cavitation, noise, and vibration

- Better propulsion efficiency in low-speed or steady-speed regimes

- Extended component life due to reduced dynamic loading

Why this upgrade works

Modern propeller geometries are designed using advanced hydrodynamic modelling, allowing for blade shapes that deliver improved loading distribution and smoother tip flow. Reblading, which retains the original hub while replacing the blades, offers a cost-effective path to substantial performance improvements with shorter downtime.

Dry-dock workflow

A typical upgrade includes removing the existing blades or full assembly, installing the optimised blade set, verifying alignment and clearances, and conducting sea trials to confirm performance. Once implemented, the efficiency benefits are consistent and long-lasting.

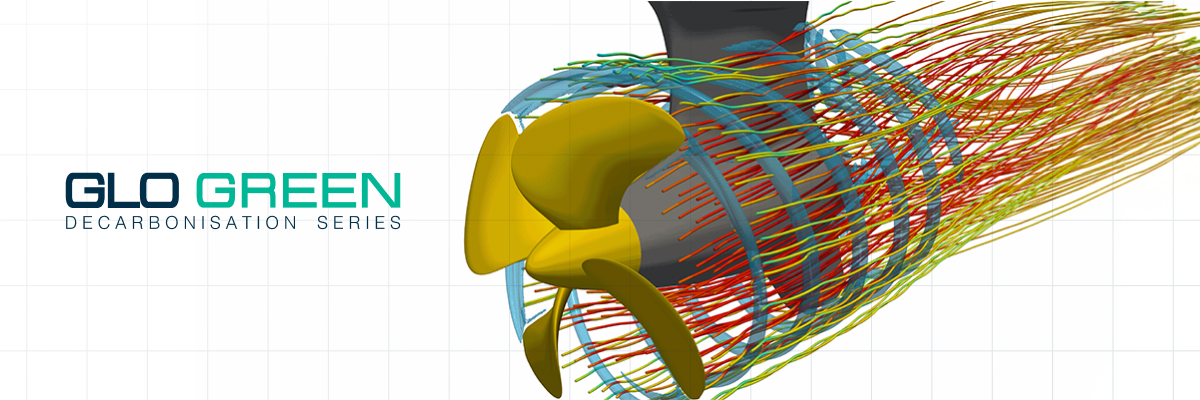

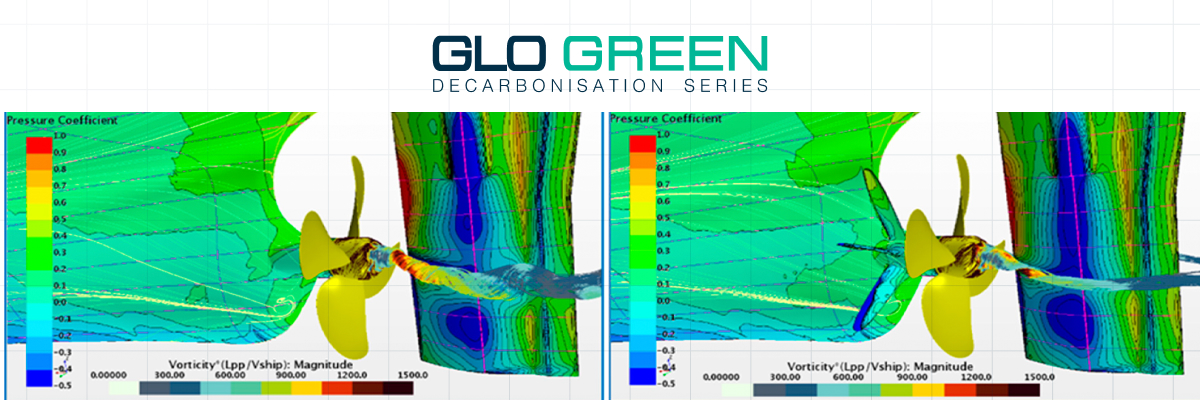

3. Pre-swirl stators: Conditioning the flow before it reaches the propeller

Hull-induced flow irregularities can significantly influence propeller performance. Pre-swirl stators address this challenge by reshaping the incoming water before it reaches the propeller disc. This solution is particularly effective on single-screw vessels with substantial aft interaction, such as tankers and bulk carriers.

Documented Benefits

- Fuel consumption reductions of 2–6%

- A more uniform inflow field

- Improved blade loading and wake performance

- Compatibility with other energy-saving devices

How stators improve efficiency

Installed ahead of the propeller, the stator fins introduce a corrective flow angle that counteracts the natural swirl created by the hull. This enhances the propeller’s ability to convert rotational power into thrust and reduces wake losses behind the vessel.

Installation requirements

During dry-docking, stator fins are welded into predetermined positions, alignment is validated, and post-installation sea trials are conducted. The device operates passively with minimal maintenance needs.

Engineering-led decision making: Why vessel-specific assessment matters

Although each upgrade delivers standalone value, their real impact depends heavily on how a vessel behaves in real operating conditions. Factors such as stern geometry, engine loading, and wake characteristics vary significantly between ships. For this reason, choosing between PBCF, a new propeller design, stators, or a combination requires a detailed engineering assessment.

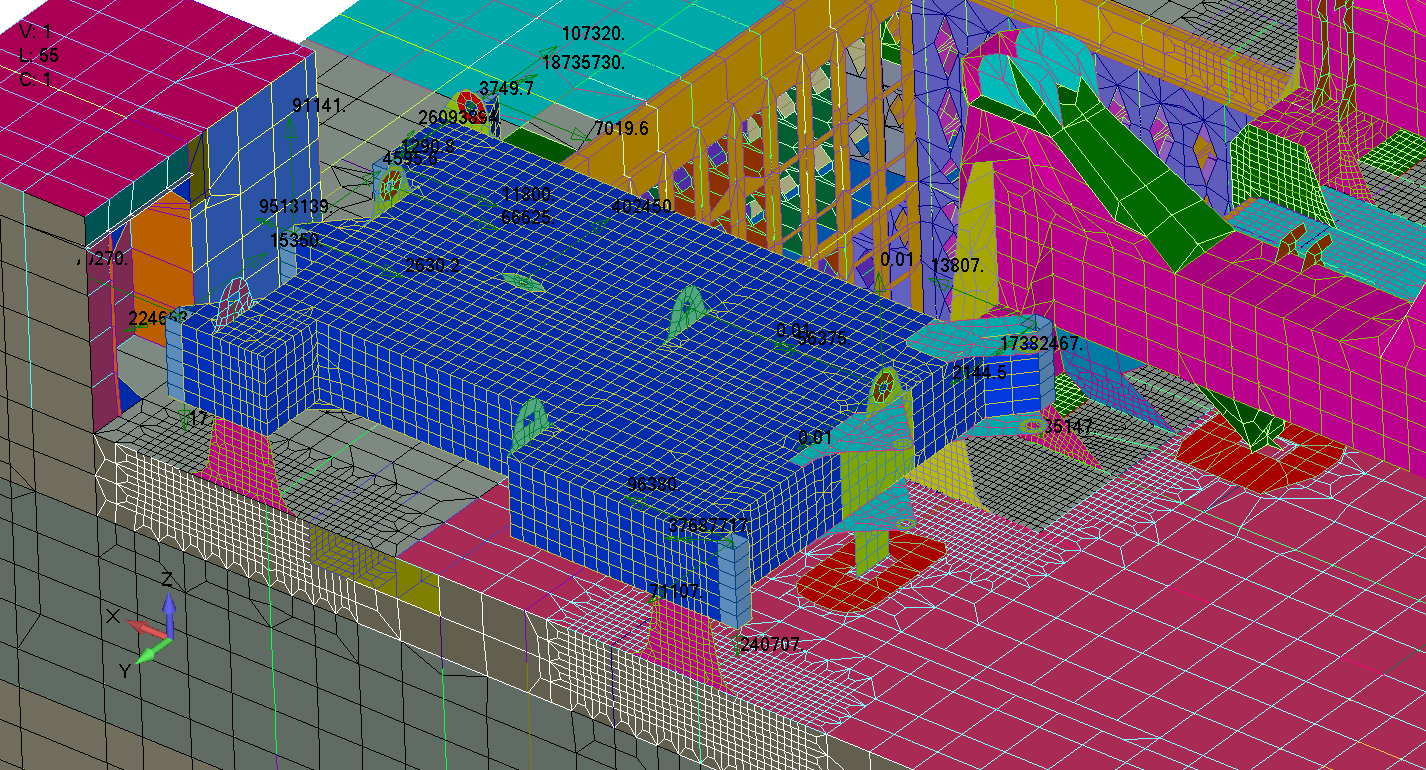

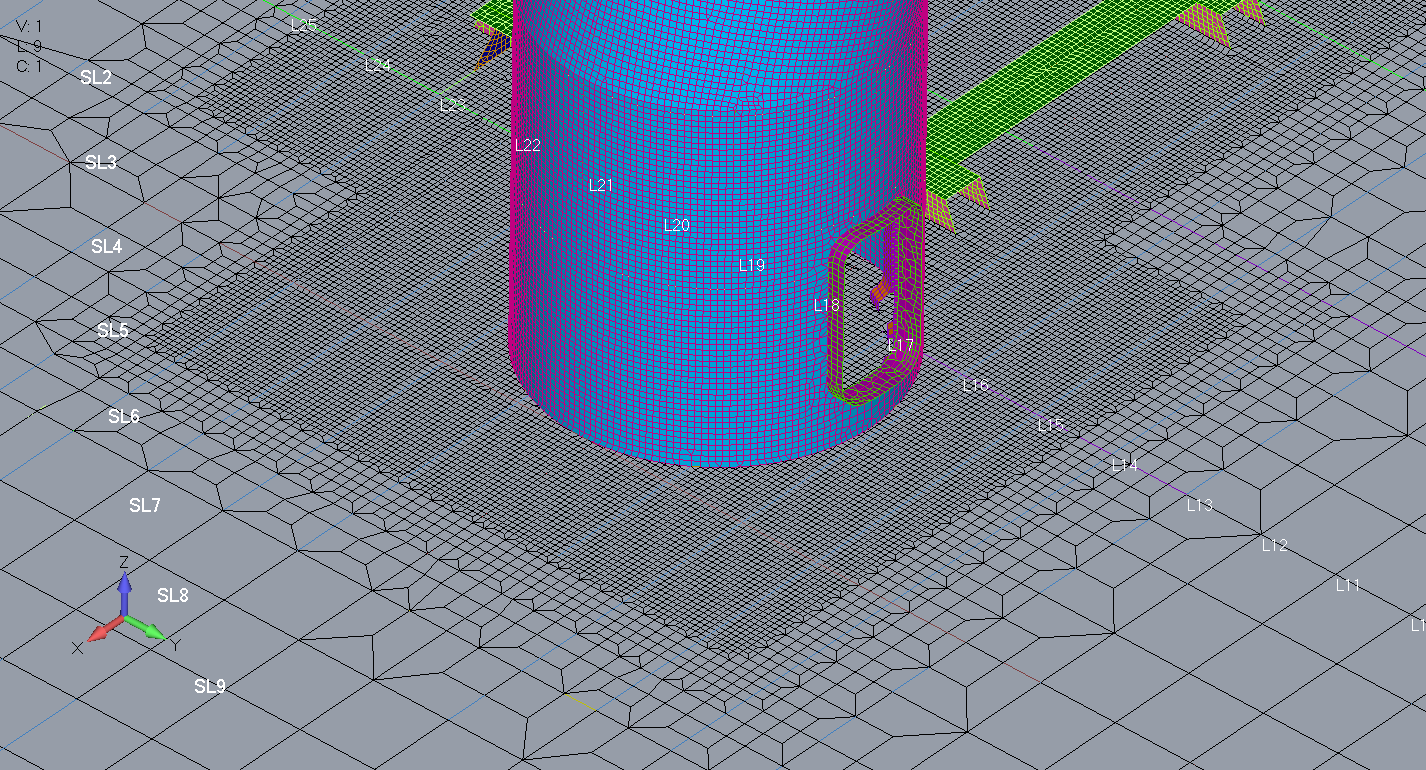

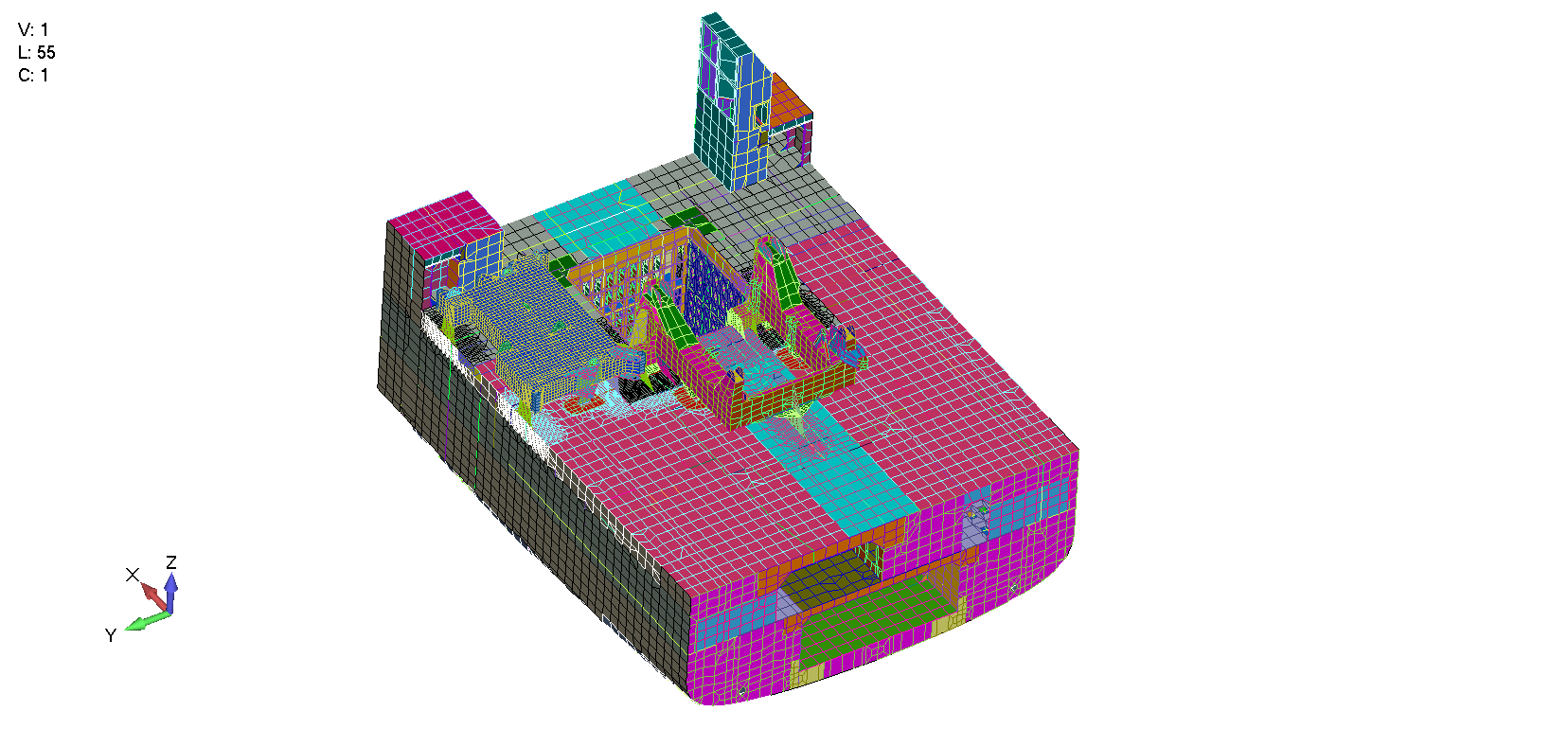

GLO Marine’s engineers rely on advanced simulation tools, vessel-specific performance modelling, and experience with complex retrofit projects to recommend the upgrade strategy with the highest return on investment.

How GLO Marine supports shipowners

Our team provides an end-to-end approach that includes:

- CFD-based stern flow and propeller performance analysis

- Evaluation of how retrofit packages affect EEXI and CII

- Engineering design, integration studies, and structural assessments

- Dry-docking support and installation oversight

- Sea-trial data interpretation for performance validation

Our goal is to deliver solutions that are technically rigorous, operationally reliable, and aligned with the vessel’s long-term lifecycle.

Conclusion

Propeller upgrades remain one of the most effective ways to improve propulsion efficiency and reduce fuel consumption. Whether implemented individually or as a combined retrofit package, technologies such as PBCF, high-efficiency propeller designs, and pre-swirl stators provide substantial and predictable performance gains when selected through a vessel-specific engineering approach.

By partnering with GLO Marine, shipowners gain access to a team that understands both the hydrodynamic science and the operational realities of successful retrofit projects — ensuring that every upgrade results in measurable value.