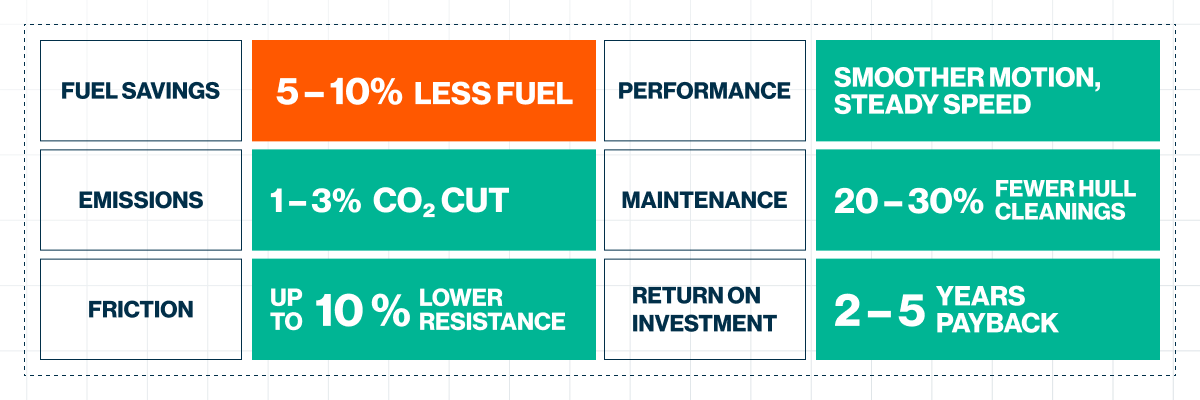

Shipping companies worldwide are racing against time to meet decarbonization targets and comply with the IMO’s CII framework. One of the most promising retrofit technologies leading this transformation is the Air Lubrication System (ALS). Already installed on a wide range of vessels, from cruise ships and LNG carriers to container vessels and ro-ro ships, ALS technology consistently demonstrates fuel savings of 5–10%, reduced CO₂ emissions, and lower maintenance costs thanks to decreased hull friction and biofouling.

Why Air Lubrication Systems are gaining global momentum

The shipping industry faces increasing pressure to cut greenhouse gas emissions and reduce operational costs while maintaining competitiveness. ALS technology directly addresses these needs by enhancing energy efficiency and ensuring regulatory compliance across different vessel types and trading routes.

Key benefits of ALS for shipowners and operators

- Fuel efficiency: By reducing friction between the hull and seawater, vessels maintain service speed with less engine power. Depending on the vessel type and operating profile, operators typically achieve fuel savings of 5–10%, which translates into substantial OPEX reductions across the fleet.

- Environmental compliance: Lower fuel consumption directly reduces CO₂ emissions. Many ALS installations report 1–3%+ carbon reductions, contributing to IMO 2030 and CII compliance while strengthening sustainability credentials in a market increasingly driven by ESG factors.

- Hull protection & longevity: Air bubbles form a protective layer between the hull and seawater, significantly reducing corrosion and biofouling. This lowers the frequency of dry-dock maintenance, extends hull coating lifespans, and improves vessel availability.

- Strong economic return: While ALS requires upfront CAPEX, the combination of long-term fuel savings, reduced maintenance, and avoidance of non-compliance penalties delivers a compelling ROI for shipowners and fleet managers.

Selecting the right ALS technology

Not all ALS solutions are equal. Providers differ in design approach, energy demand, sensitivity to sea states, and resilience to minor groundings. Choosing the right system depends heavily on vessel type, operating speed, and draft.

At GLO Marine, we provide end-to-end solutions, including engineering guidance to help owners evaluate options and select the most suitable ALS technology for their fleet profile and operational requirements.

Engineering challenges in ALS retrofit projects

Successful ALS implementation goes beyond choosing a vendor. It requires careful vessel modifications across multiple disciplines:

- Hull modifications – installation of nozzles, penetrations, and localized reinforcements.

- Machinery spaces – compressor foundations, ventilation upgrades, and layout adjustments.

- Piping systems – addition of air distribution lines and integration of cooling water connections.

- Electrical & automation – power load balancing, switchboard updates, and integration of ALS controls.

- Regulatory compliance – revised General Arrangement (GA), updated EEXI/CII documentation, and safety assessments.

These adjustments require a coordinated, multidisciplinary approach to safeguard vessel integrity and guarantee maximum efficiency.

How GLO Marine Supports ALS Installations

With global experience in ship retrofits and decarbonization technologies, GLO Marine brings together its hull, piping, electrical, automation, and commissioning teams to deliver seamless ALS retrofit projects. From feasibility studies and engineering design to installation support and commissioning, we ensure every ALS installation achieves its promised performance and contributes to sustainable shipping.

Future-proofing your fleet with ALS

As regulators tighten emissions requirements and fuel costs remain volatile, ALS offers a proven, scalable pathway for shipowners looking to boost competitiveness while aligning with decarbonization goals.

At GLO Marine, we don’t just deliver engineering—we deliver confidence in performance, compliance, and ROI.

Ready to explore ALS retrofits for your fleet? Discover how the decarbonisation plan developed by GLO Marine, can help you navigate regulatory challenges, reduce emissions, and turn compliance into a competitive edge. Explore the full details here and start charting your roadmap to a greener future today.