3D Laser Scanningfor millimeter level accuracy

Contact our specialists

3D Scanning performed by maritime professionals

GLO Marine operates its own specialised team of engineers and marine surveyors dedicated to performing the 3D Laser Scanning and on-board survey tasks required for retrofit and conversion projects for vessels in operation.

We use FARO 3D scanning technology to capture the "as-built" conditions of the vessel, providing accurate measurements and high details of the existing pipe and structure.

We can scan your vessel.

Any time, no downtime.

Our dedicated teams are ready to be deployed at any time, quality equipment and similar experience allow us to perform the most accurate scans in just a day.

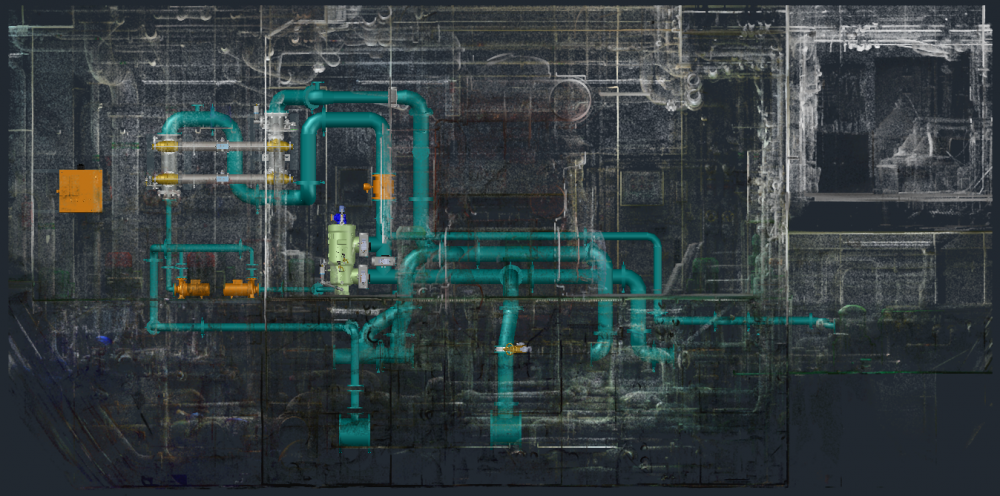

The 3D scans are then processed in a point cloud to create the exact geometrical representation of complex spaces. Based on it, designers can develop a model of a structure

and/or plant, its machinery, piping, and equipment for Concept Design – Basic, Detailed, and As-Built Engineering.

3D Scanning in

BWTS retrofits

No engine room is the same, thus making BWTS retrofit a unique process for each ship. Highly detailed 3D laser scanning is an accurate and efficient solution to determine the feasibility, impact and conflicts associated with installing the ballast water treatment system and associated piping on board vessels.

To ensure the perfect fit, the existing structure needs to be scanned and modeled with very high precision and used in the design and fabrication of new components or structures.

The use of laser scanning in BWTS helps shipyards deliver projects faster, more efficiently, and with less risk. On top of this, laser scanning can be done while the ship is in operation. The advantages of 3D laser scanning are the reduction in time of installation, the costs and failures.

Do you need a

Ballast Water Treatment System Installation?

We can offer you a complete engineering package.

BWTS Services

Benefits of using

3D Laser Scanning

The FARO 3D Laser Scanning technology creates a point cloud of millions of data points containing information that is used to create the most accurate 3D image of a space and all objects inside it.

Designing based on point cloud is extremely accurate and effective, once prepared point cloud of the vessel’s spaces can be used at any stage of modification – from feasibility study to project in development. It is also a valuable element constituting a kind of delivery documentation after reconstruction.

-

HIGH LEVEL OF

ACCURACY -

MINIMUM

DOCKING TIMES -

REDUCED

MANMADE ERRORS -

COST EFFICIENT

SOLUTION